PROPERTIES

NOtES

- Carbon Boards (1200ºC heat treated) are rigidized PAN long fiber felt.

- Only Stocked in 60in x 40in x all thickness on Pricing sheet with foil on 2 sides. Raw and one sided carbon board has a 1-3 week lead time.

- Graphite Boards (2000ºC heat treated) are shaved Rayon foam stocking in (60 x 40in) & (52 x 24in) size with foil on 1 side for shipping in 1 week.

- Boards can be lined (covered) on one or both sides with;

- Graphite foil (0.015 in. thick) = add $50 per side.

- CFC (carbon-fiber-composite) (0.030 in. thick) = add $250 - $450 per side.

- Board thickness capability up to 20 in. thick

- High temperature heat treatment up to 2600°C & halogen purification available. Priced at time of quote.

- Rigidized felt has courser fiber & so better for oxidation resistance & heat treating vacuum furnace or hot pressing applications.

- Check out our CUSTOM SHAPE prices!

PRICING (as of 9/2017)

SDS Sheet

Rigid Felt Board Properties

Rayon Sliced Foam Board Properties

Applications

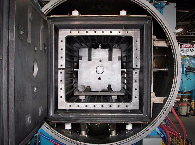

- Graphite rigid insulating boards in PAN rigidized felt or Rayon sliced foam are used insulation for vacuum & protective atmosphere process furnaces.

- The boards are easily cut or machined to size to fit both square and round hot zones.

- The boards can be machined into complex shapes and made to print in large sizes

- Surfaces & cut edges can be sealed using our Graphite Coating.

- Repairs and connections are made using one of our family of Graphite Adhesives.

- Graphite foil added to the surface or layered in the board increases radiant heat retention significantly as wellas reduces issues with furnace contaminent containment

- Foil helps decrease pump down times and increase longevity of the insulation.

- Similarly, CFC covering on the boards gives durability, impact & wear resistance.