Pan & Rayon Differences

- PAN (PolyAcrylNitrile) is lower in cost.

- PAN has coarser fiber and larger fiber diameter = Lower Surface area.

- PAN is stiffer and has an "ichier" feeling. Rayon is more flexable and less irritating to the skin

- Rayon is lower in Thermal Conductivity than PAN at temperatures greater than 1800°C.

For heat treating applications, PAN carbon felt is the best price.

For handling ease and ultra high temperatures, Rayon is the best choice.

....

Discounts available!

- High volume, 9 rolls or more!

- High Purity processing, Heat treated up to 2600C & halogen purified.

- Cut to Length

- Less than a roll quantities are 25% more per square foot.

- $100 minimum order for less than a roll.

Pricing

Carbon Felt

SDS Sheet

Applications

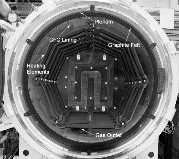

Soft Carbon and Graphite Felts are used as insulation in vacuum and protective atmosphere (non-oxidizing) furnaces and process equipment used in the heat treating, semi-conductor, ceramic, aerospace, defense, bio-medical appliance, and sintered metals industries. These felts are also used as a cathode in flow battery applications and as a reaction surface for many other electro-chemical processes. Common consumer and industrial consumable uses are as welding blankets, plumber pads, glass blowing pads, wicks in ultralight stoves, and automotive exhaust lining.

Credit: Ipsen